Includes: Pottery and ceramics, pottery colouring, engraving and decoration of gypsum products and artifacts

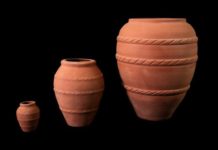

In Bahrain, the village of A’ali is known for its pottery industry, which began about five thousand years ago. The clay is supplied locally from Riffa and is greatly appreciated by the potters for its quality, as it enables them to work and mould a great many designs, shapes and sizes in an array of decorative colour finishes. The spinning wheel is made of stone and circular shaped. The potter operates the wheel by means of a foot paddle. The clay is previously beaten in unique containers and then mixed with the water which makes it ready for ‘throwing’.

Bahrain’s most famous potter owns a 200-year-old pottery workshop, a showroom for their numerous hand-made wares, which they have produced from childhood having been taught by their fathers and grandfathers, going back to old transport, donkey and cart days.

Making a special clay pot usually takes up to five working days to finish. The wet clay has to dry in the sun until just moist enough to work with, and then has several hours of being ‘worked’ by the potter on the spinning wheel. Lastly baked in a gas furnace: (new gas furnaces were installed by the government in 2001, thereby cutting pollution along with the improved safety measures.)

Since Dilmun period times, Bahrain has quarried gypsum, which has been artistically made into various decorative features above doorways, ceilings, wall panelling, in mosques, in Rifā Fort and in Bahraini family homes. Gypsum décor is easily spotted and appreciated for the many beautiful designs and its enhancement.

Currently, Bahraini combined expertise produces both traditional and modern “work of art”, including wall hangings of traditional doors, false ceilings with ornamental designs and even a steel design structure made to order!

In Bahrain there are few workshops offering different styles of gypsum design, giving an idea of just how popular their specialty trade is to the people of Bahrain.