Myanmar traditional lacquerware emerged in the early part of Bagan Period (eleventh century AD). In Myanmar, it is known as pan yun, which refers to a handicraft that produces materials made of bamboo, wood and thick black varnish (resin or sis-se).

The raw material used to manufacture the objects is bamboo. The bamboo used to make the inner part of the lacquerware comes from the forests of the Chin State, which is transported by boat to Bagan. The bamboo then is cut out, softened and worked to give the shape of the desired object.

In the first stage of lacquering, the interior is covered with thayo, a resin paste with lacquer and mixed ashes. This work is usually carried out by hand. The number of times where the object of layers will be coated determines the quality of the lacquer. The craftspersons who carry out this work have used this technique for many generations. When an application is made on the bamboo mould, one must then dry it in a dark and wet place. The duration of drying is approximately a week.

Once finished drying, the lacquer is carefully washed and sandpapered if necessary. This stage is important for the quality of the future lacquer. This washing and sandpapering is carried out with charcoal, resulting from very common trees in Myanmar like teak. After the first drying, the object is carefully sandpapered, washed, then another coat is applied, then dried again. As one adds more coats, the mixture is increasingly fine, taken from ash of ox bone.

When the new layer is well spread out, any finger marks are erased with a fine fabric. The object thus is coated several times, then dried. Each time it thus receives a new layer of lacquer. It is only the last layer that one colours. The colours are usually red, green, blue or yellow. The colour is obtained by adding powder of mercury cinnabar to the lacquer. This mixture is called hinthapyada.

After last drying for the seventh or eighth times, the lacquer is again sandpapered with teak wood ash, then washed carefully and it then will be decorated. Engraving is done with free hands, without model, entirely of memory, using a stylus and brush.

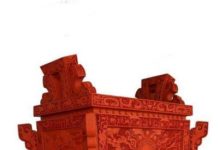

Small and large objects are lacquered. This process is applied to crockery and objects of workshop. But lacquer with beautiful colours is also used on larger objects such as pieces of furniture, the cupboards, the tables, large decorative objects, the musical instruments and earthenware jars, etc. After carrying out all these process, the lacquerware are now marketable throughout the country and overseas. The condition of lacquerware craft in Myanmar is quite healthy.

Process of Lacquer-ware making

\