There are two main types of pottery made in Sarawak: hand-moulded, low-fired utility wares made by the indigenous people, and wheel-thrown prestige pottery introduced by Chinese immigrant artisans. Locally made pottery, some of it ceremonial ware, has been found in several archaeological sites. Clay cooking and storage vessels were produced up until the 20th century when imported metal pots became commonly available.

Local potters, mostly women, produced wares almost exclusively for home use, mainly for cooking. Instead of using a wheel, pots were built up of lumps of clay or, in some cases, coils. The body of the vessel was shaped by holding a smooth pebble in the inside while smoothing by hand on the outside. Carved paddles were occasionally used to impress decorative patterns on the outside of pots.

After drying, clay pots were fired in an open pyre at some distance from the longhouse. Once the wares reached red heat, they were considered “done”, and were cooled slowly to prevent cracking. In some cases, hot vessels were tossed in piles or rice bran to make them more watertight.

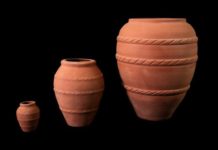

The people of Borneo have long treasured prestige ceramics imported from China and Vietnam in the ninth and tenth centuries. About 200 years ago, some Teochew-speaking Chinese potters from the Chaoshan region of eastern Guangdong province started to set up kilns in Borneo. They turned out utility wares for the local market, including large brown-glazed pots for water and other domestic storage. These jars found a ready market among the local population though they were never equated with the heirloom pieces of earlier times.

The Chinese potters use locally available clay, throw their products on the potter’s wheel and finish them with waterproof glazes inside and out. Underglaze decorations in a rainbow of colours are painted on before the products are dried and fired in a “dragon kiln”, a wood-fired sloping tunnel kiln. Place names like Tanah Puteh (white earth) and Sungai Priok (pot river) near Kuching mark the sites of old potteries.

Today, the potteries produce mainly souvenir wares for the tourist market. Some of it is fired in oil- or gas-fired furnaces, rather than traditional dragon kilns, while the indigenous potters have practically ceased production in the face of aluminium and plastic.